In today's trucking industry, AI systems are transforming truck repair processes by leveraging machine learning and natural language processing. These technologies predict issues from data, enhance speed and accuracy in repairs, minimize downtime, and optimize efficiency. Through automation and data-driven insights, AI automates tasks, improves communication, and boosts component inspection accuracy. Best practices for implementation include maintaining high-quality data, starting with simple tasks like predictive maintenance, and gradually expanding to complex areas. This approach ensures technician familiarity while streamlining operations and boosting productivity in truck repair.

In today’s competitive transportation industry, optimizing truck repair workflows is crucial. This article delves into the challenges faced by the sector and explores how AI technologies can revolutionize repair operations. We discuss leveraging AI systems for efficient parts identification, diagnostic support, and predictive maintenance. Furthermore, best practices for implementing and optimizing these AI systems are provided to streamline truck repair processes, reduce downtime, and enhance overall fleet productivity.

- Understanding Current Challenges in Truck Repair Workflows

- Leveraging AI Technologies for Efficient Repair Operations

- Implementing and Optimizing AI Systems: Best Practices

Understanding Current Challenges in Truck Repair Workflows

In the fast-paced world of trucking, efficient and accurate truck repair workflows are non-negotiable. However, traditional methods often face significant challenges. The current landscape is characterized by complex maintenance requirements, tight deadlines, and a shortage of skilled technicians, leading to inefficiencies and increased costs. Manual processes, like diagnostic testing and inventory management, can be time-consuming and prone to human error.

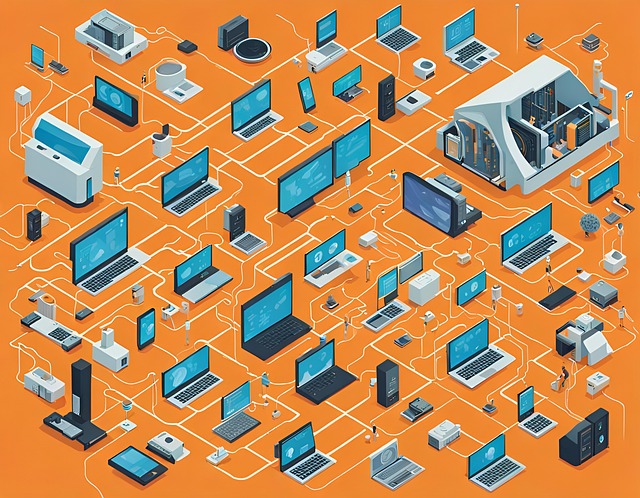

AI systems emerge as powerful tools to streamline truck repair operations. By leveraging machine learning algorithms and natural language processing, AI can analyze vast amounts of data from sensors and maintenance records to predict potential issues before they become major repairs. Automated inventory management reduces stockouts and optimizes parts ordering, while intelligent scheduling enhances technician efficiency. These strategies not only enhance the speed and accuracy of repairs but also contribute to improved safety on the road by minimizing downtime and ensuring trucks are in optimal condition for transportation.

Leveraging AI Technologies for Efficient Repair Operations

In today’s digital era, leveraging AI technologies has become a game-changer in optimizing various industries, and truck repair operations are no exception. AI systems for streamlining truck repair operations offer unprecedented efficiency gains by automating repetitive tasks and providing valuable insights. These intelligent solutions can analyze vast amounts of data from previous repairs, maintenance records, and even real-time sensor data to predict potential issues before they become costly breakdowns.

For instance, machine learning algorithms can identify patterns in common repair scenarios, enabling technicians to proactively address problems. Natural language processing (NLP) enhances communication between the AI system and human workers, ensuring clear instructions and accurate reporting. Additionally, computer vision algorithms can inspect and diagnose components with remarkable accuracy, reducing manual inspection time and minimizing human error.

Implementing and Optimizing AI Systems: Best Practices

Implementing and optimizing AI systems is a game-changer for truck repair workflows, offering significant advantages in efficiency and cost savings. To maximize the benefits, it’s essential to adopt best practices. Firstly, ensure data quality and accessibility; AI systems heavily rely on accurate and comprehensive data. Standardize data collection processes, regularly update records, and make them easily retrievable for analysis.

Secondly, integrate AI solutions gradually. Start with simple tasks like predictive maintenance or diagnostic support, allowing technicians to familiarize themselves with the technology. As expertise grows, expand AI roles to more complex areas such as inventory management or parts procurement, ultimately streamlining truck repair operations and enhancing overall productivity.

AI technologies have the potential to revolutionize truck repair workflows by streamlining processes, reducing costs, and improving efficiency. By leveraging machine learning algorithms and natural language processing, repair shops can automate mundane tasks, provide accurate diagnostics, and optimize inventory management. Implementing AI systems requires a strategic approach, including data collection, model training, and continuous improvement. Following best practices ensures that AI optimization strategies are tailored to the unique needs of truck repair operations, ultimately enhancing overall productivity and customer satisfaction.